Standard GH hoist regenerative inverter

Energy savings, environmental sustainability and customer cost savings

THE GH SOLUTION:

- GH manufactures standardised hoists and cranes with drive control by means of frequency inverters.

- The incorporation of regenerative modules gives our equipment great advantages for our customers.

ADVANTAGES

- Energy savings.

- Contribution to the sustainability of the environment.

- Rapid amortization of the investment (ROI).

HOW IT WORKS

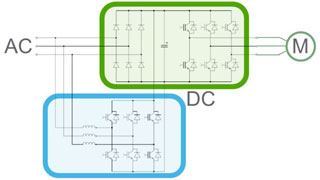

- The ATVR is a networked regenerative braking module which means that it returns to the network the energy produced by a motor when it retains a load.

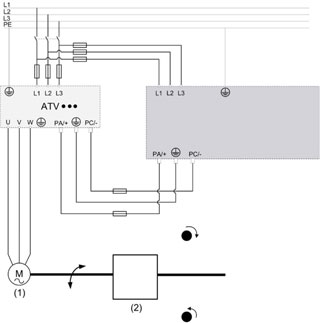

- This module is connected to the DC bus of any frequency inverter and to the network.

- When the motor starts to function as a generator instead of dissipating the energy as braking resistors do, the equipment returns it to the network to be reused at other points of consumption.

- Several frequency inverters can be connected at the same time with a single module, making it possible to eliminate the resistors for the 3 movements of the crane.

- It is a more efficient way of braking than the conventional method, reducing the electricity consumption and the carbon dioxide (CO2) footprint of the facilities.

LOOKING FOR A COMPANY AND SOLUTION THAT EXCEEDS YOUR EXPECTATIONS? Request a quote